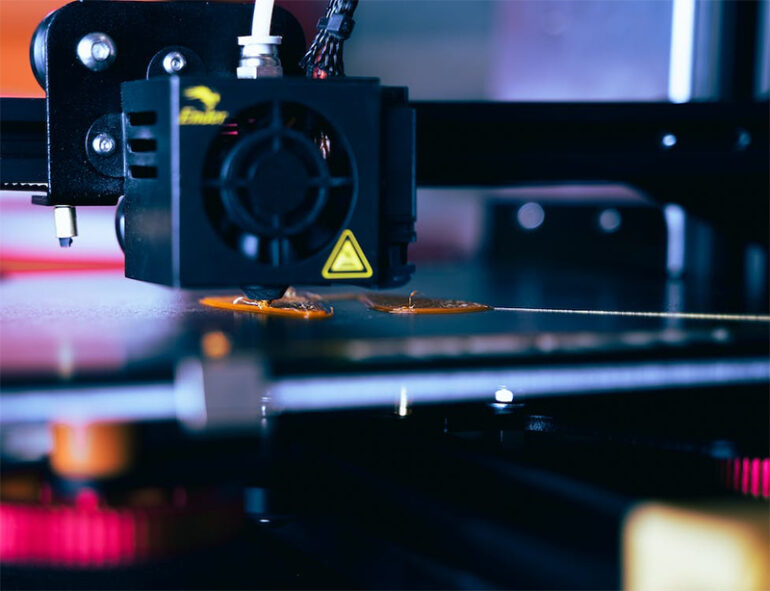

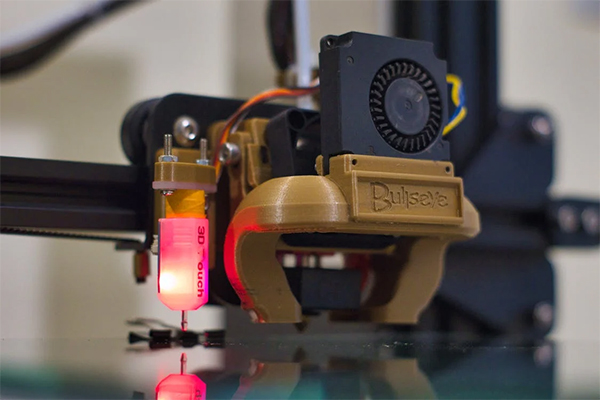

By first using software to create a three-dimensional model or simply a 3D model and then transferring this blueprint to a 3D printer, creating a real-life model of that same virtual model is made possible. To be more specific, the printer uses a filament made from powdered or liquid plastic, cement, or metal as its “ink” and then prints out layers that would then congeal themselves together and create a 3D form. Since 3D printers have become integrated within multiple industries, double-checking dimensions, testing different designs or prototypes, and making scale models have never been simpler and cost-effective for companies.

History

The first record of any 3D printer was during the late 1980s when Charles W. Hull first used a technique called stereolithography. Initially using Hull’s technique was costly with hardware setting companies back between five and six figures. Today, 3D printing has become so popular that there are even companies selling consumer-grade 3D printers.

Uses For Artists

While most people are focused on 3D printing’s uses for large-scale companies, this new technology has been starting to gain attention in the art world. Unlike conventional sculpting methods that take a great amount of space, raw materials, and a limited margin of error, 3D printing gives artists the option of being able to revise details to their liking and more space to work. In addition, there are artists who have also started to make replicas of previous works of other artists using 3D printing, a few of these replicas even look indistinguishable from the original because these prints can also capture the exact brush strokes and textures as seen on the original canvas. As a result of this, there are a few institutions that use these replicas to teach students about the history of art and the unique techniques and skills it took to create them.

Uses In Architecture

It is well known that architects make scale models of their designs to decide if there is anything missing or to present their design to a client but making a scale model can be both time-consuming and pricy. And both these dilemmas can be easily solved by 3D printing. A large portion of architects today already use CAD programs to show a mock-up of their design and transferring this file and letting the 3D printer make the model instead will save them valuable time to work on other projects. Furthermore, intricate designs and harsh or difficult shapes will not need to worry about them anymore because 3D printers can create just about any shape and finish the whole model within a few days of printing.

Behind 3D printing, there is both intention and precision, but at the same time, there is also freedom and artistry. 3D printing creates what feels like a limitless plane for creativity, it is a safe space where new innovations and designs can be first tested and tweaked. It seems that almost any industry has found a use for this ground-breaking technology, without 3D printers, companies would need more time to prototype and design products before deciding that they are ready for the market.

Photo Attribution:

1st and featured image by https://www.pexels.com/photo/black-and-yellow-camera-on-black-table-8865186/

2nd image by https://www.pexels.com/photo/black-and-yellow-metal-tool-4485456/